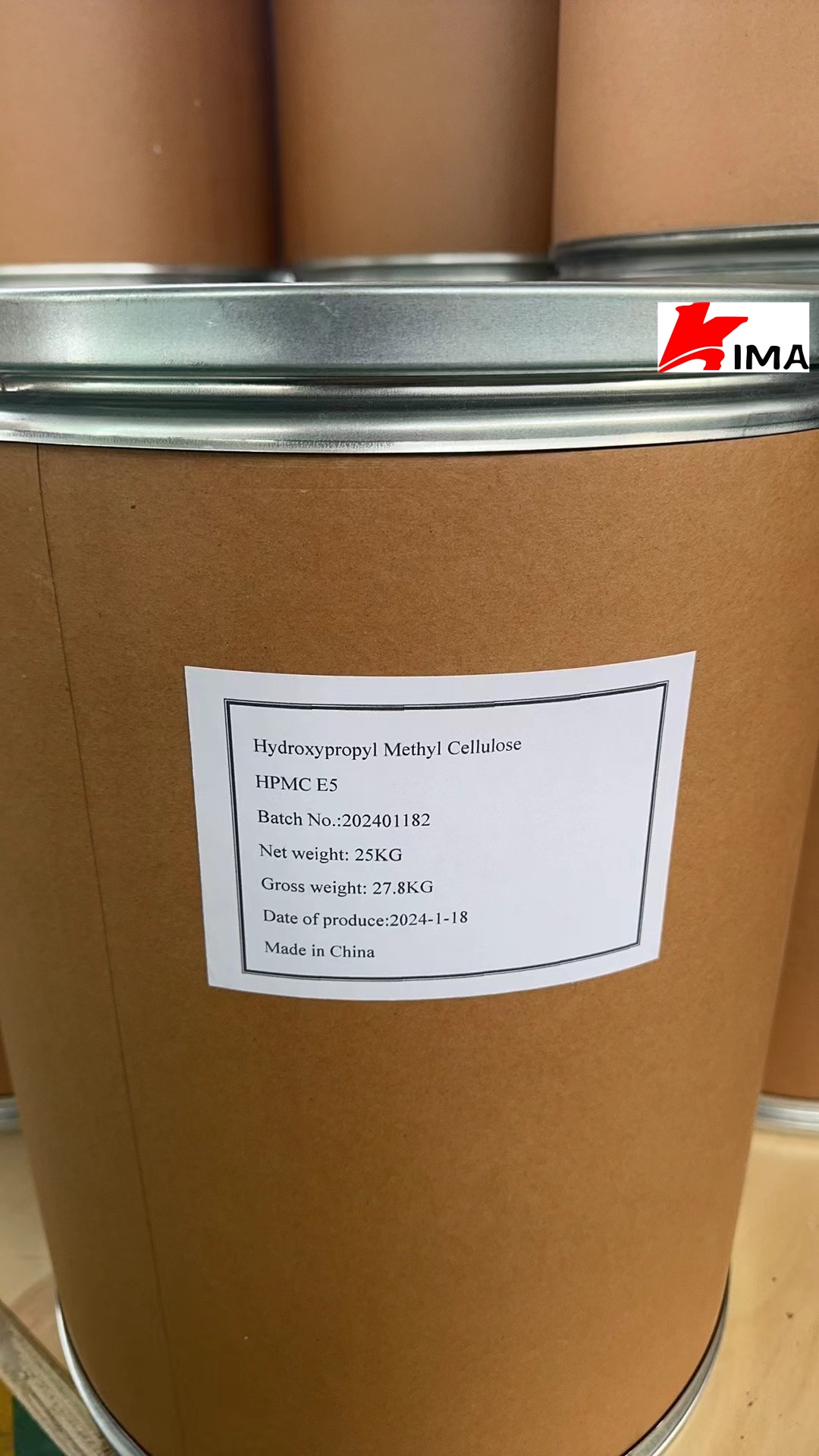

Hydroxypropyl Methylcellulose | Baking Ingredients

1. Introduction to Hydroxypropyl Methylcellulose (HPMC) in Baking:

Hydroxypropyl Methylcellulose (HPMC), a cellulose derivative, has gained popularity as a versatile ingredient in the baking industry. Its unique properties make it an excellent additive for improving texture, moisture retention, and shelf life in baked goods. In this guide, we will explore the role, benefits, types, and application techniques of HPMC in baking.

2. Chemical Structure and Properties of HPMC:

HPMC is synthesized through the chemical modification of cellulose, where hydroxypropyl and methyl groups are introduced onto the cellulose backbone. This modification imparts desirable properties to HPMC, including:

- Thickening

- Water retention

- Film-forming ability

- Stability in various formulations

3. Role of HPMC in Baking:

In baking, HPMC serves multiple functions, including:

- Texture Improvement: HPMC improves the crumb structure and texture of baked goods, resulting in a softer and more uniform crumb.

- Moisture Retention: It helps retain moisture in baked products, preventing them from drying out and prolonging shelf life.

- Volume Expansion: HPMC promotes volume expansion during baking, leading to increased rise and improved overall appearance.

- Gluten Replacement: HPMC can partially replace gluten in gluten-free or low-gluten formulations, enhancing the elasticity and structure of baked goods.

4. Benefits of Using HPMC in Baking:

The use of HPMC in baking offers several benefits, including:

- Enhanced texture and crumb structure

- Improved moisture retention and freshness

- Increased volume and rise in baked products

- Better stability and shelf life

- Gluten-free and vegan-friendly options for specialized diets

5. Types and Grades of HPMC for Baking:

HPMC for baking is available in various types and grades, each with specific properties suited for different applications. Key considerations include viscosity grades, particle size distribution, and degree of substitution (DS).

5.1 Viscosity Grades:

- Low-viscosity grades are suitable for liquid batters and doughs, providing excellent dispersion and hydration.

- High-viscosity grades are ideal for thicker batters and doughs, offering enhanced thickening and binding properties.

5.2 Particle Size Distribution:

- Narrow particle size distribution ensures uniform dispersion and consistent performance in baked goods.

5.3 Degree of Substitution (DS):

- The DS affects the solubility and gelation behavior of HPMC, influencing its thickening and stabilizing properties in baking applications.

6. Application Techniques and Dosage:

HPMC can be incorporated into baking formulations using various techniques, including:

- Dry blending with dry ingredients

- Pre-hydration in water or other liquids before adding to the batter or dough

- Direct addition to the batter or dough during mixing

Dosage of HPMC depends on factors such as desired texture, moisture content, and specific application requirements. It is typically used at levels ranging from 0.1% to 2% of the total flour weight.

7. Formulation Examples Using HPMC:

Example 1: Gluten-Free Bread

- Ingredients: Gluten-free flour blend, water, yeast, sugar, salt, HPMC

- Method: Mix dry ingredients, hydrate HPMC in water, add to dry ingredients, knead, proof, and bake.

Example 2: Cake Batter

- Ingredients: Flour, sugar, eggs, oil, baking powder, milk, flavorings, HPMC

- Method: Cream sugar and eggs, add dry ingredients, hydrate HPMC in milk, add to batter, mix, and bake.

8. Considerations and Tips for Bakers:

- Ensure thorough dispersion and hydration of HPMC to avoid clumping and uneven distribution in the batter or dough.

- Experiment with different grades and dosages of HPMC to achieve the desired texture, volume, and moisture retention in baked goods.

- Consider the specific requirements of gluten-free or vegan formulations when selecting HPMC for baking applications.

9. Conclusion:

Hydroxypropyl Methylcellulose (HPMC) offers bakers a versatile ingredient for improving texture, moisture retention, and volume expansion in baked goods. Its unique properties and multiple functions make it a valuable additive in various baking applications. By understanding the types, grades, and application techniques of HPMC, bakers can enhance the quality and appeal of their baked products while meeting consumer demands for texture, freshness, and dietary preferences.

Post time: Apr-02-2024