Water retention of HPMC in masonry mortar

As we all know, the theory of complete hydration of cement requires 26% of the cement mass, and the actual water consumption of mortar greatly exceeds the water required for hydration of cement in the mortar, which is mainly to meet the needs of construction. The strength of cement stone is mainly related to the water-cement ratio related. The greater the water-cement ratio, the greater the porosity of the cement stone, the lower the strength of the cement stone, and the lower the strength of the mortar. Therefore, as long as the water retention performance of the masonry mortar ensures the operability of the mortar and the moisture required for the hydration of the cement in the mortar.

If the water retention of the masonry mortar is too good, the actual water retained in the mortar will be greater, the real water-cement ratio of the mortar will be greater, the actual strength of the mortar will be lower, and the bond strength will also decrease. lowered. In addition, the water retention of the mortar is too good, and the water is not easily absorbed by the block material, which will also affect the bonding between the cement slurry and the block material, and prolong the setting time of the mortar, thereby affecting the speed of masonry and increasing the difficulty of construction. Therefore, the water retention index of masonry mortar should correspond to that of the block material.

If the pore structure of the block material is open, and the block material is easily permeable by water, such as fired bricks, the water retention of the masonry mortar can be lower, and more than 80% can be used, such as ordinary bricks fired with traditional mortar for masonry very effective.

If the pore structure of the block material is closed, the porosity is high, the block material is not easily penetrated by water, or the block material is not allowed to be wetted by water during construction, then the water retention of the masonry mortar should increase the mortar moisture content to meet the medium Required for cement hydration. For example, in the construction of autoclaved lime-sand bricks, if masonry mortar with a water retention rate of 80% is used to build lime-sand bricks, the water retention of the mortar is low, and the moisture in the mortar is easily absorbed by lime. Sand bricks, resulting in a serious shortage of water required for cement hydration in the mortar joints, so that the cement hydration cannot be carried out normally, reducing the real strength of the mortar and the bonding strength of the mortar and the lime-sand brick. This is also one of the reasons why traditional mortar masonry is easy to crack. Therefore, the water retention of mortar for masonry bricks should be controlled above 88%.

However, if we increase the water retention rate of the mortar of the masonry bricks to more than 95%, it will be difficult to absorb the moisture at the joints of the mortar, the actual strength of the mortar will decrease, and the bond strength between the brick and the wall will also decrease. Mortar and bricks will also be reduced. The water retention of the mortar is too good, the bricks are not easy to adhere to the mortar during masonry, and the mortar is stable, and the height of the masonry is limited.

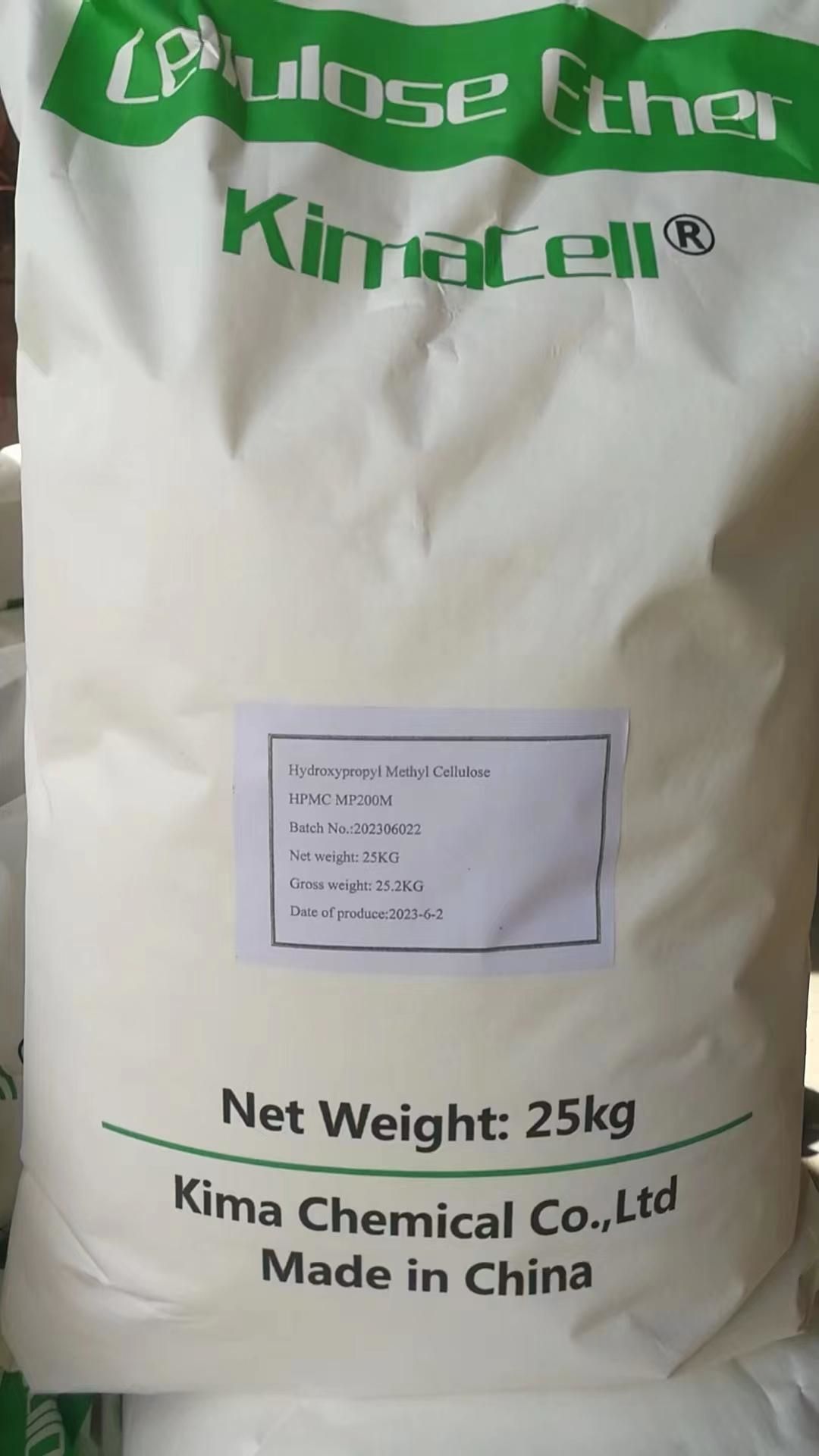

Therefore, the water retention of hydroxypropyl methylcellulose in masonry mortar is not as high as possible, and different block materials should have a suitable water retention range.

Post time: Jun-14-2023