Clavis verba: hydroxypropyl yl cellulosum;PVC cum alto polymerizatione gradu;experimentum parvum;polymerization;localisatio.

Applicatio Sinarum hydroxypropyl methylcellulosumloco importato ad productionem PVC altae polymerizationis gradus introductae sunt.Effectus duorum generum hydroxypropyl methylcellulosi in proprietatibus PVC cum gradu polymerizationis altorum investigati sunt.Eventus ostendit id hydroxypropyl yl cellulosum domesticum substituere posse ad unum importatum.

Gradus summus polymerizationis PVC resinae referuntur ad resinas PVC cum mediocriter polymerizationis plusquam 1,700 vel structurae leviter transversalis inter moleculas.Comparata cum ordinaria resina PVC, resina polymerization PVC altam habet mollitiam, compressionem parvam, resistentiam caloris, resistentiam senescentis, resistentiam lassitudinem et resistentiam induendi.Specimen Flexilis substitutus est et adhiberi potest in fasciolis autocinetis obsignandis, filo et cable, catheteri medici, etc.

Productio methodus PVC cum eminentia polymerizationis maxime polymerizationis suspensio est.In methodo suspensionis producenda, dispersor est agens auxiliaris magni momenti, eiusque typus et quantitas directe afficiunt particulam figuram, particulam distributionem, et effusio plasticizer resinae perfectae PVC.Communiter systemata dispersionis adhibita sunt systemata alcohol polyvinylum et hydroxypropyl methylcellulosum et alcohole polyvinyl systemata dispersionis composita, et artifices domestici his plerumque utuntur.

I Praecipua rudis materiae et specificationes

Praecipuae materiae rudis et specificationes in probatione adhibitae in Tabula 1. Exhiberi potest e Tabula 1 quod hydroxypropyl methylcellulosum domesticum in hac charta delectum consentaneum est cum hydroxypropyl methylcelluloso importato, quod praerequiritur pro probatione substitutionis in hac. chartac.

2 Test content

2. 1 Praeparatio hydroxypropyl solutionis methylcellulosae

Quandam quantitatem aquae deionizationis accipias, eamque in vas et calefacies ad LXX°C, et gradatim adde hydroxypropyl methylcellulosam sub assidua agitatione.Aquam primo innatat cellulosa, deinde paulatim digeritur, donec aequaliter misceatur.Frigus solutionem voluminis.

Tabula 1 Praecipua materiarum rudium et eorum specificationum

| Rudis materia nomen | Specification |

| Vinyl chloride monomer | Qualitas score≥99.98% |

| Desalinated aqua | Conductivity≤10.0 μs/cm, pH valorem 5. 00 ad 9. 00 |

| Polyvinyl alcohol A | Alcoholysis gradus 78.5% ad 81.5%, cinere content≤0.5%, materia volatilis.0% |

| Polyvinyl alcohol B | Alcoholysis gradus 71.0% ad 73.5%, viscositas 4. 5 ad 6. 5mPa s, materia volatilis.0% |

| Polyvinyl alcohol C | Alcoholysis gradus 54.0% ad 57.0%, viscositas 800 ~ 1 400mPa s, solida contenta 39.5% ad 40. 5% |

| Importari hydroxypropyl methylcellulosum A | Viscositas 40 ~ 60 mPa s, metoxylus massa fractio 28% ~ 30%, hydroxypropyl fractio massae 7% ~ 12%, humor≤5.0% |

| hydroxypropyl methylcellulosum domesticum B | Viscositas 40 ~ 60 mPa · s, metoxylus massa fractio 28% ~ 30%, hydroxypropyl fractio massae 7% ~ 12%, humor ≤5.0% |

| Bis(2-ethyl peroxydicarbonate) hexyl niensis) | Missae fractio [(45~50) ± 1]% |

2. 2 Test methodus

In X L fabrica parva test, hydroxypropyl methylcellulosum importat utere ad probationes deducendas probationes fundamentales ut formulam parvam test fundamentalem determinare;hydroxypropyl methylcellulosum domesticum utere ad hydroxypropyl methylcellulosum invectum ad probationem invectum;Resinae producti PVC per hydroxypropyl methylcellulosum producti comparati sunt, et facultas reponendi hydroxypropyl methylcellulosum domesticum quaesitum est.Secundum eventus parvae probationis, productio probatio exercetur.

2. 3 Test vestigia

Ante reactionem, munda polymerizationem ahenum, claude valvulam imam, adde quantitatem aquae desalinatae, et postea adice dispersam;operculum ollae claudere, evacuare post nixum nitrogenium transitum test, et adde monomer vinyl chloridi;post frigidum motum, initiatorem adde;Utere aqua circulando ut temperiem in olla movendo ad temperiem moveat, et solutionem ammonium bicarbonatam opportune modo addas durante hoc processu ad valorem pH reactionis systematis accommodandi;cum pressionis reactionis guttae ad pressionem in formula specificata, terminatorem et defoamer adde et solutionem emittunt.Perfectum resinae PVC productum per centrifugationem et siccationem consecutus est, et pro analysi gustatum.

2. 4 Analysis methodi

Secundum methodos examinis in expeditionis norma, viscositas numerus, densitas apparentis, materia volatilis (inclusa aqua) et effusio plasticizer 100 g PVC resinae resinae confectae PVC examinatae sunt et enucleatae;Mediocris magnitudinis resinae PVC particula probata est;morphologia particularum PVC resinae mediante microscopio inspecto observatum est.

3 Results and Discussion

3. 1 Analysis comparativa qualitatis diversorum batches resinae PVC in parvae polymerizatione

Press 2. Secundum probationis methodum in 4, quaelibet massae minimae peractae PVC resinae probata est, et eventus in Tabula 2 monstrantur.

Tabula 2 eventus diversorum batches parvae test

| Batch | Hydroxypropyl methylcellulosum | densitas apparentis/(g/mL) | Mediocris magnitudinis particula / μm | Viscositas/(mL/g) | Plasticizer effusio 100 g PVC resinae/g | Materia volatilis/% |

| 1# | Import | 0.36 | 180 | 196 | 42 | 0.16 |

| 2# | Import | 0.36 | 175 | 196 | 42 | 0.20 |

| 3# | Import | 0.36 | 182 | 195 | 43 | 0.20 |

| 4# | Domestic | 0.37 | 165 | 194 | 41 | 0.08 |

| 5# | Domestic | 0.38 | 164 | 194 | 41 | 0.24 |

| 6# | Domestic | 0.36 | 167 | 194 | 43 | 0.22 |

Ex Tabula 2: Apparens densitas, viscositas numerus et effusio plasticizer consecuti PVC resinae inter se proximae sunt utendo celluloso pro minimo experimento;resina producto hydroxypropyl methylcelluloso utens domestica formula Mediocris particulae magnitudine paulo minor est.

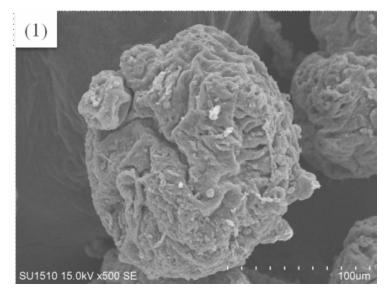

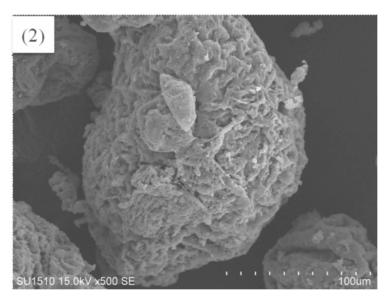

Figure 1 SEM imagines resinae PVC productas ostendit adhibitis hydroxypropyl methylcellulosis diversis adhibitis.

(I) -Imported hydroxypropyl methylcellulose

(2) -Domestic hydroxypropyl methylcellulosum

Fig.1 SEM resinae in 10-L productae polymerizer coram hydroxypropyl yl celluloso diversae.

Ex Figura 1 constare potest structuras superficies particularum resinarum PVC a diversis cellulosis dispersantibus productas similes esse.

Ad summam, videri potest hydroxypropyl methylcellulosum domesticum in hac charta probatum habere facultatem reponendi hydroxypropyl methylcellulosum importatum.

3. 2 Analysis comparativa qualitatis resinae PVC cum gradu polymerizationis magno in test productio

Ob magnum sumptus et periculum productionis test, schema integrum tortor parvae testi directe applicari non potest, ideo consilium est ut paulatim augeat proportionem hydroxypropyl methylcellulosae domesticae in formula.Proventus probati cuiusque massae in Tabula 3 monstrantur.

Tabula 3 Test eventus diversorum productionis batches

| Batch | m (China hydroxypropyl yl cellulosa): m (invecta hydroxypropyl yl cellulosa) | densitas apparentis/(g/mL) | Viscositas numerus / (mL/g) | Plasticizer effusio 100 g PVC resinae/g | Materia volatilis/% |

| 0# | 0:100 | 0.45 | 196 | 36 | 0.12 |

| 1# | 1.25:1 | 0.45 | 196 | 36 | 0.11 |

| 2# | 1.25:1 | 0.45 | 196 | 36 | 0.13 |

| 3# | 1.25:1 | 0.45 | 196 | 36 | 0.10 |

| 4# | 2.50:1 | 0.45 | 196 | 36 | 0.12 |

| 5# | 2.50:1 | 0.45 | 196 | 36 | 0.14 |

| 6# | 2.50:1 | 0.45 | 196 | 36 | 0.18 |

| 7# | 100:0 | 0.45 | 196 | 36 | 0.11 |

| 8# | 100:0 | 0.45 | 196 | 36 | 0.17 |

| 9# | 100:0 | 0.45 | 196 | 36 | 0.14 |

Ex Tabula 3 videri potest usum hydroxypropyl yl cellulosi domestici sensim augeri usque dum hydroxypropyl yl cellulosum domesticum penitus reponit hydroxypropyl yl cellulosum importatum.Praecipui indices sicut effusio plasticizer et densitas apparentis signanter non fluctuabat, significans hydroxypropyl methylcellulosum domesticum in hac charta electum reponere posse hydroxypropyl methylcellulosum in productione importatum.

4 conclusio

Expertus hydroxypropyl yl cellulosus domesticus in 10 L fabrica parva experimentalis ostendit se invectum hydroxypropyl yl cellulosum reponere posse;productio substitutionis testium proventi ostendunt hydroxypropyl yl cellulosum domesticum pro productione resinae PVC adhiberi, praecipuae qualitates indicibus resinae confectae PVC et hydroxypropyl yl cellulosae importatae nullam differentiam significantem habere.Nunc pretium cellulosum domesticum in foro humilius est quam cellulosa importata.Si igitur cellulosa domestica in productione adhibeatur, sumptus productionis subsidiorum significanter minui possunt.

Post tempus: Nov-04-2022